BUILT ON EXPERTISE. DRIVEN BY EXCELLENCE.

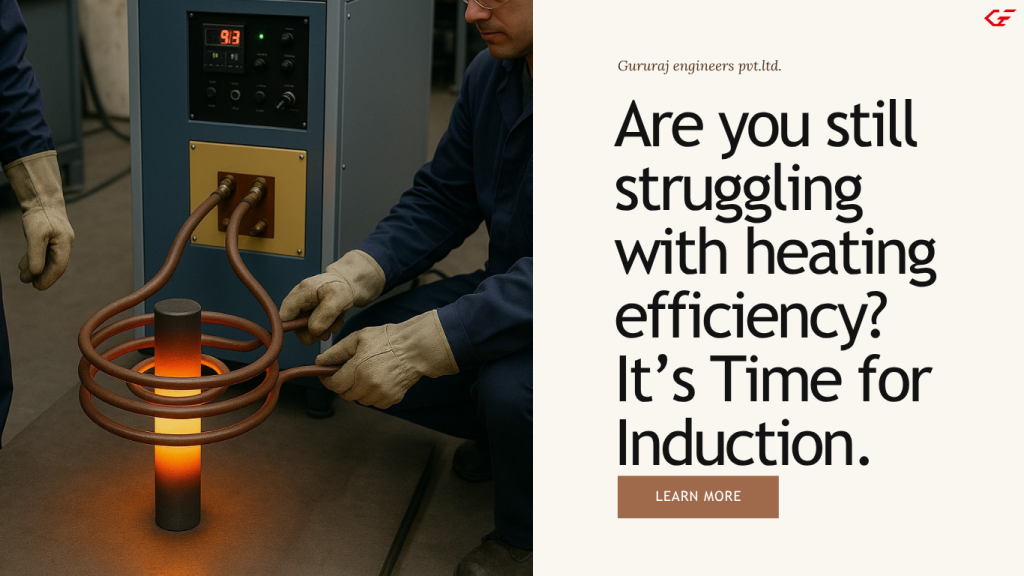

Are you still struggling with heating efficiency?

It’s Time for Induction

In the evolving world of industrial automation, every second counts — and so does every degree. Heating systems are at the heart of many critical processes, from metal treatment to pre-welding to shrink-fitting. Yet, many manufacturers still rely on outdated heating methods that are slow, inefficient, and inconsistent.

If you’re experiencing long heating cycles, excessive energy usage, or poor temperature control, it’s time to make the switch.

What Is Induction Heating?

Induction heating is a non-contact process that uses electromagnetic fields to heat metal directly and precisely. Unlike traditional methods like flame or resistance heating, induction offers instant, targeted, and controllable heat — making it a game-changer in automated environments.

Where It Works Best

At Gururaj Engineers Pvt. Ltd., we supply and support induction heating solutions for:

- Shaft hardening & annealing

- Pipe & tube heating (round and square)

- Brazing & soldering

- Pre-weld heating

- Heat shrinking

- Customized OEM applications

If your operation still relies on slow, energy-hungry heating systems, it’s time to ask:

Are you still struggling with heating efficiency?

Then it’s time to move to induction — it’s time to move forward.