BUILT ON EXPERTISE. DRIVEN BY EXCELLENCE.

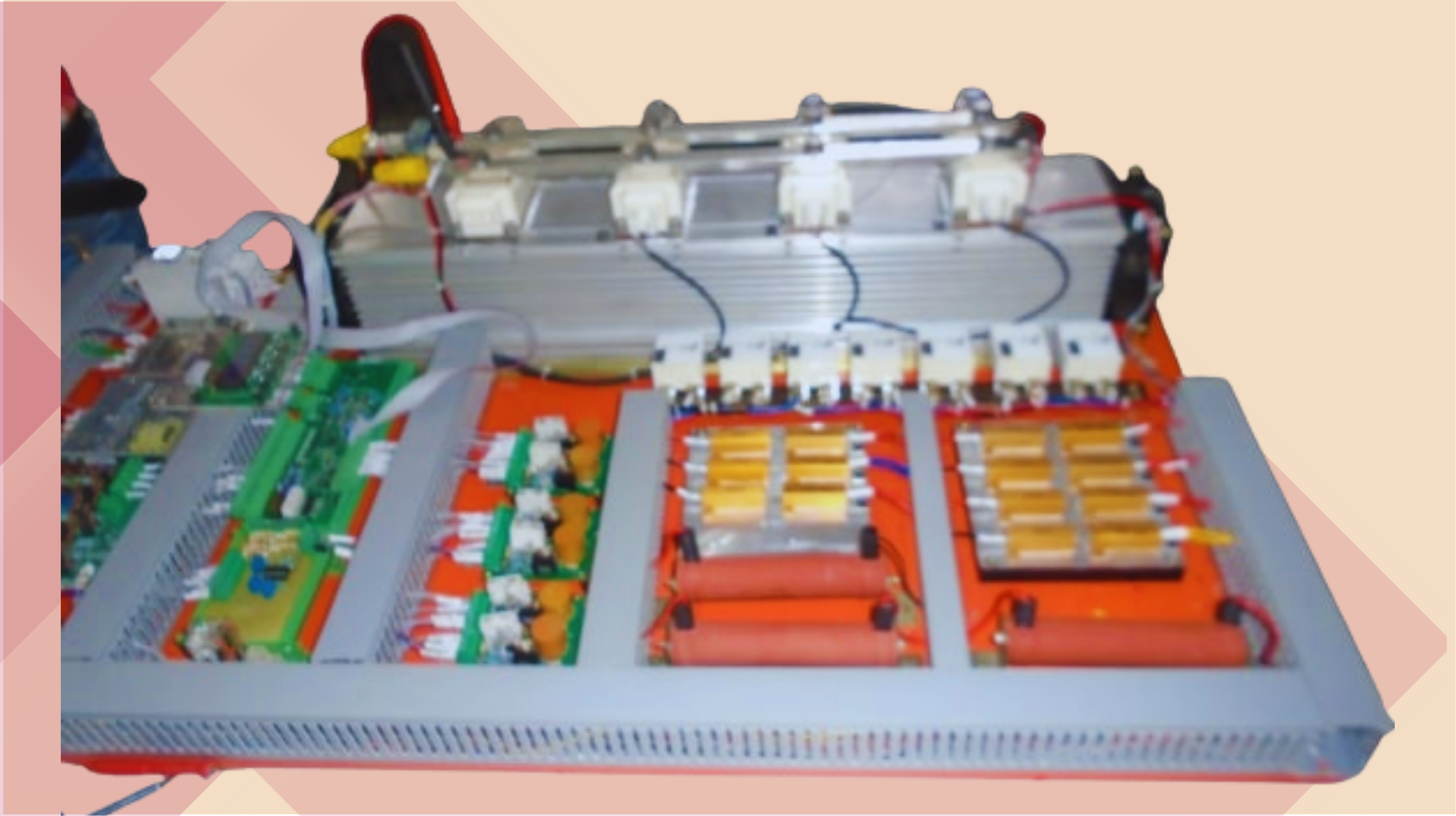

THYRISTORIZED HEATER POWER CONTROLLERS

Description:

- Temperature in furnaces and ovens are controlled using thyristorized power controllers for heaters.

- Very precise control of temperature is possible using PID temperature controller with thyristorized power controller

Applications:

- Current rating from 40A to 300A

- Voltage rating 480Vac , 600Vac, 690Vac

- Single, Two and Three phase

- Firing mode configuration “Zero crossing” (Fixed Cycle,Burst Firing, or “Phase angle”)

- Configurable analogue inputs: mA, V, Potentiometer

- Current limit and current trip

Product Details:

Description:

- Temperature in furnaces and ovens are controlled using thyristorized power controllers for heaters.

- Very precise control of temperature is possible using PID temperature controller with thyristorized power controller

Applications:

- Current rating from 40A to 300A

- Voltage rating 480Vac , 600Vac, 690Vac

- Single, Two and Three phase

- Firing mode configuration “Zero crossing” (Fixed Cycle,Burst Firing, or “Phase angle”)

- Configurable analogue inputs: mA, V, Potentiometer

- Current limit and current trip

Specifications:

Heater Connections (1 Phase / 2 Phase / 3 Phase Star / Delta) – Specifies the wiring configuration of the heater, which can be single-phase, two-phase, or three-phase in either star (Y) or delta (Δ) connection, affecting voltage and current distribution.

Heater Line-to-Line Voltage – The voltage measured between two phases in multi-phase heater connections, critical for proper operation and efficiency, commonly 230V or 400V.

Heater Power (kW) Total per Zone – The total power consumed by the heater in a specific zone, measured in kilowatts (kW), indicating heating capacity and energy usage.

Number of Zones – Defines the number of independently controlled heating sections within the system, allowing precise temperature regulation in different areas.

Temperature Range – Specifies the minimum and maximum temperatures the heater can achieve, ensuring suitability for specific applications (e.g., 50°C to 300°C).

Temperature Stability (± °C) – Indicates the heater’s ability to maintain a steady temperature within a given tolerance range, minimizing fluctuations (e.g., ±2°C).